| |

LASER PRECISION MICRO CUTTING

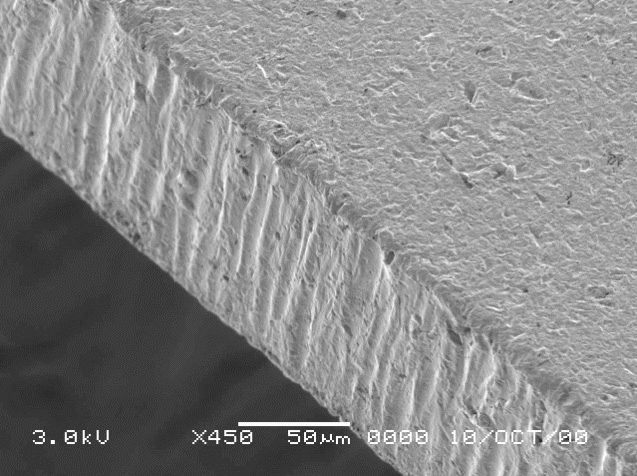

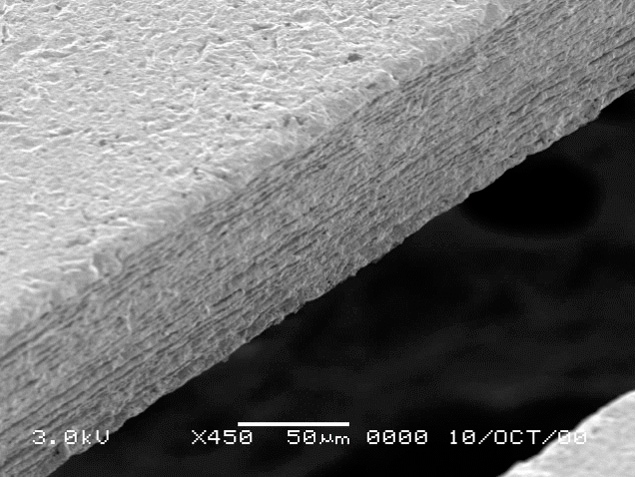

Laser precision micro cutting in the production of SMT stencils is the latest technology, and it gives us a better quality

product in terms of definition, precision, repeatability and wear resistance.

It also reduces the execution time,

even when the boards to fit have particularly critical components.

The material normally used to make the metal foil

is STAINLESS STEEL. This material is available in the following thicknesses: 100 - 120 - 150 - 200 Micron with tolerances

on the thickness of + / - 5%.

The tolerances applied to this technology as far as the "openings" achieved are

concerned are + / - 0.01 mm. Four laser machines for stencil production are installed at Lasertech.

Drawings

Files in the following formats are necessary for making metal foils and stencils: standard gerber files (RS274D), extended

gerber files (RS274X), DPF files (BARCO), 9XXX files, DWG, DXF files (autocad).

To be able to carry out specific and accurate controls and correct opening sizing, it is necessary to receive the solder

paste file and board file (copper) in addition to the opening wheel.

You can use the SMT stencil request to ask

for a specific machining or offer, sending it together with the respective files.

|

|

| |

|

Equipement

Continuous collaboration with customers and suppliers makes it possible to offer a set of SMT process support equipment made according

to the specific needs of every manufacturing company such as, for example:

- Mini Stencils for reworking and reballing stations

- Component inspection fixtures

- Scraper bar holder and metal scraper bars for any silk-screen printing system.

Our technical department is at your disposal for all SMT process machining and application job you might need.

This states our vocation, the crossroads where the customer´s needs coincide with our experience and service. |

|

| |

|

|

| |

|