| |

SMT STENCILS

Technology

Experience gained in the production of traditional silk-screen printing screens - above all for the production of

printed circuits - has typified the production of stencils used in SMT technology over the years ever since this

technology made its first appearance. SMT STENCILS can be supplied in the form of complete silk-screen printing

screens or metal foils for self-tensioning systems achieved with all the processes available on the world market

for meeting any need:

- Photochemical milling

- Laser precision cutting and micro cutting on metal

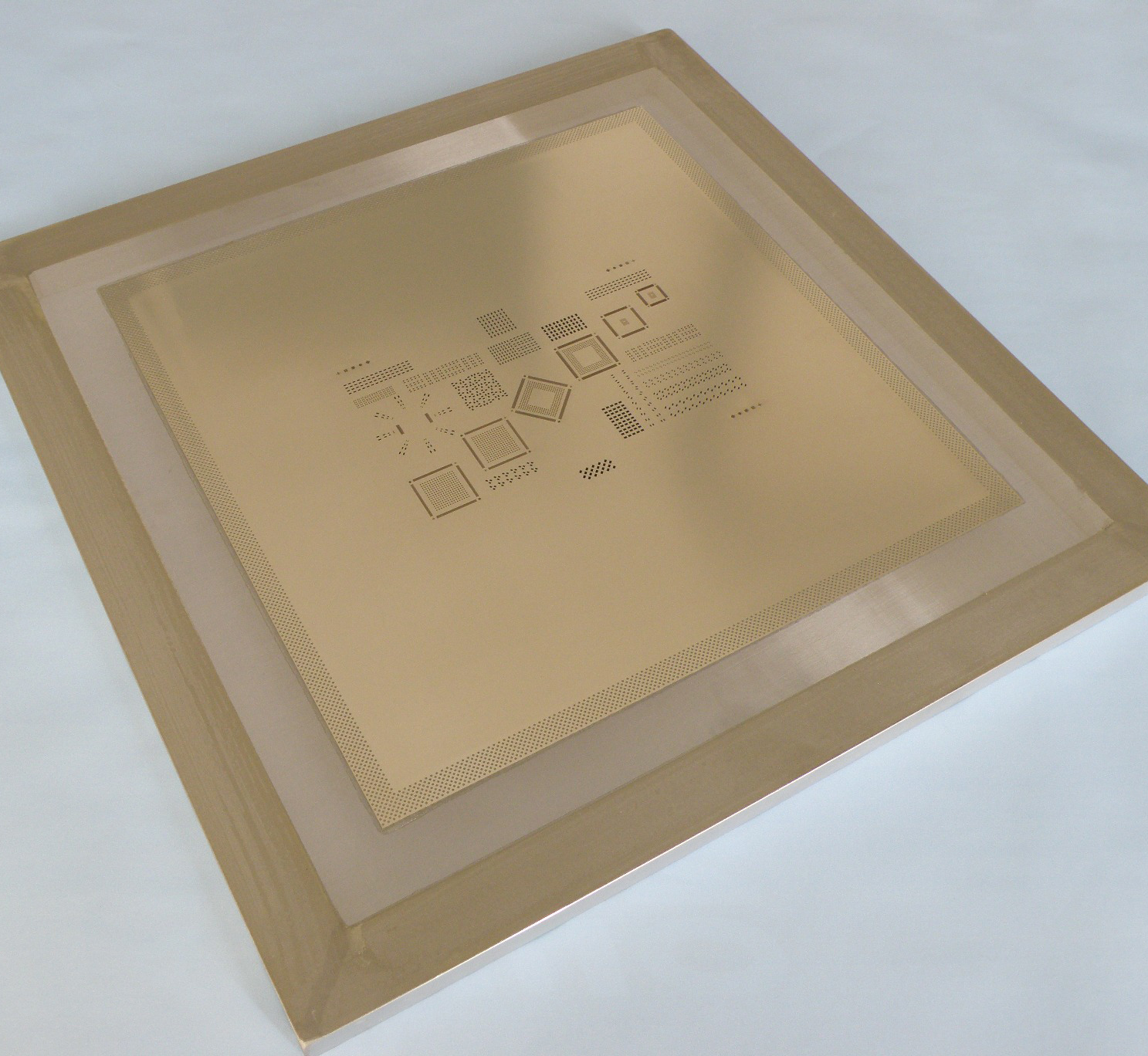

Silk-screen printing screens

Frame: made of aluminium to a specific drawing with sections of a particularly high thickness able to ensure sturdiness,

precision and at the same time light weight and resistance to chemical agents.

Mesh: the fabric used as a the support between the frame and the metal foil is made of AISI 304 stainless steel; using

a mesh of this type results in optimum and long-lasting stretching and stability.

|

|

| |

|

Anchorage: the various parts forming the SMT stencil are glued with special adhesives having high mechanical and chemical

resistance so as to make it impervious to both water and solvent-based cleaning and washing products.

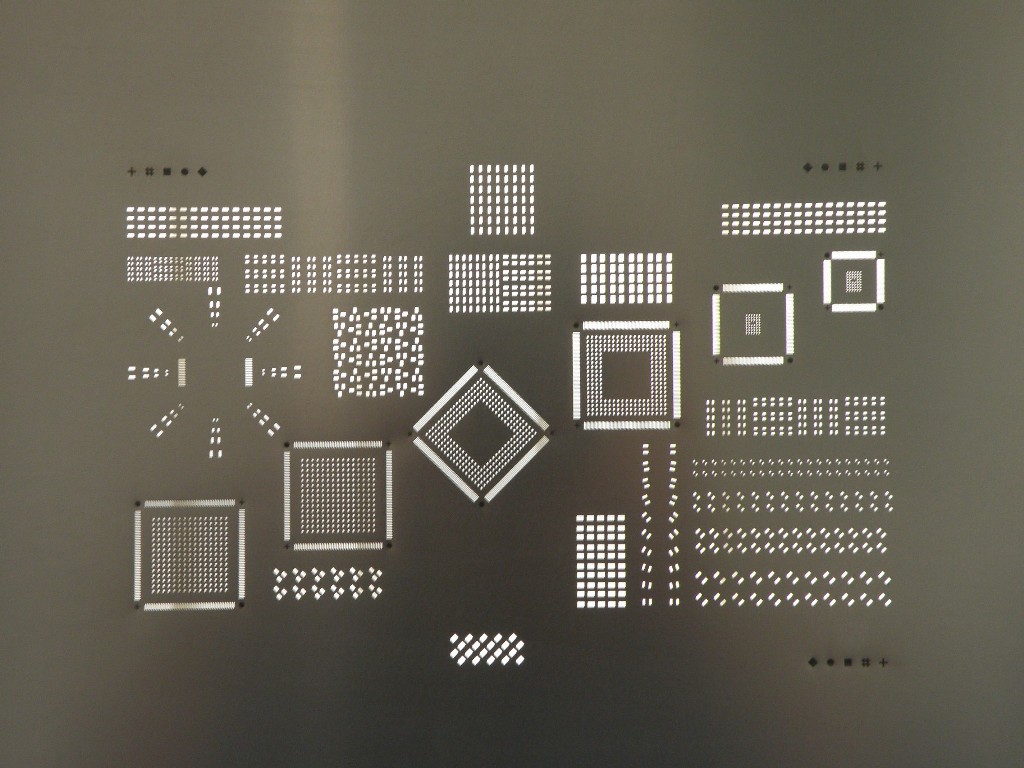

Photochemical etching

Photochemical etching is the technology also used in making SMT stencils.

It gives excellent results with a high quality to price ratio.

The material generally used to make the metal foil is

NICKEL SILVER (Cu Ni Zn20), also known by the name of NEW SILVER. BRASS can also be used for special applications.

This material is available in the following thicknesses: 100 - 150 - 200 - 250 Micron with tolerances on the thickness of + / - 5%.

The tolerances applied to this technology as far as the "openings" achieved are concerned are + / - 0.02 mm.

|

|

|

| |

|